- Home

- Products

- Corrugated Paperboard Production Line

- Corrugated Sheet Gluing Machine

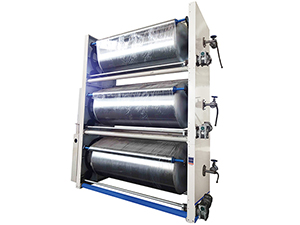

Corrugated Sheet Gluing Machine

Model: GMC-20

Features:- After gluing roller surface tempering and inner bore processing, the surface of the gluing roller is dynamic balance finely ground and engraved with 32 lines of corrugated mesh with uniform gluing and less glue consumption.

- The gluing roller rotation is controlled by frequency motor, which ensures that the linear speed of the roller is synchronized with the double facer, and can operate independently.

- Adopts automatic circulation of glue supply to effectively control the quantity of glue and avoid glue precipitation.

- The surface of each roller is treated with chrome plated after precision grinding.

- Adopts roller encoder to measure the speed signal of double facer and realize synchronous operation.

- The gluing machine adopts man-machine interface display.

- The amount of glue can be adjusted automatically with production speed. Besides, can also be manual fine-tuning in the automatic mode, easy to operate.

- Max design speed: 150m/min

- Max width: 1600mm

- Air pressure: 0.4-0.6Mpa

- Operation direction: Right or left (depend on the customer plant)

- Glue roller diameter: ¢269mm

- Stick roller diameter: ¢142mm

- Press shaft: ¢155mm

- Conveying roller diameter:¢110mm

- Glue roller main motor: 3kW

- Glue adjustment motor: 100W

- Press roller clearance adjustment motor: 100W

- Glue pump motor: 2.2kW

Inquiry Form

MAY KWA PRINTING MACHINERY CO., LTD.

Address: 51 Deyu road, Qiaonan street, Shiqiao, Panyu, 511400 Guangzhou city, Guangdong province, China

Tel.: +86-020-84877071