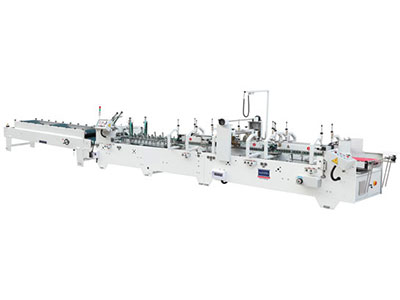

Printer Slotter (with Die Cutting and Stacking Function)

Detailed Description

The printer slotter is a kind of flexo printing machine. It is also a paper cutting machine with die cutting and stacking function.

Machine Parts and Performance Features

- Adjusting the printing unit and slotting unit is controlled by PLC for convenient and reliable operation.

- All drive shafts are made of superior-quality steel. They are surface ground and chrome plated.

- The transmission gear is made of high-quality 40Cr alloy steel with Rockwell hardness of at least 50 HRC after heat treatment.

- All units of the complete printer slotter machine is electrically separated and pneumatically locked. An audible alarm sounds continuously during operation to ensure the security of operators.

- Different rings will sound when the printer slotter starts or stops working.

- The button to start the main engine is pressed by two hands to secure the operators.

- The front, middle and rear parts of the printer slotter die cutter are configured with emergency stop switches respectively.

- The three-color LED indicator shows four statuses of the printer slotter: Power, Standby, Run and Fault.

- All units of the complete machine are designed with an emergency stop switch to stop the electrical movement of the unit, which ensures the safety of operators. A paper feeding system forces all units of the printer slotter to move.

- All electrical parts of the complete machine are sourced from world-renowned brands. This machine is designed with auto-zero function, wiping plate memory and pre-setting function. The function of motor frequency adjustment provides the printing and slotting unit with short adjustment time and high precision.

A: Lead Edge Feeder

1) Controlled by touch screen and control button, the control panel operates easily and reliably.

2) The main motor is started under the control of dual button to ensure the security of operators.

3) Continuous or skip feeding is available based on the requirements of clients.

4) The printer slotter is designed with a counter to show the number of paperboard pieces.

5) The horizontal orientated position of the shielding board adopts mechanical and electrical control system. A caliper is used to display the movement distance.

6) The caliber of the front shielding board is manually adjusted.

7) The paper feeding system comes with an 11KW fan, providing accurate feeding, quick response, low moment of inertia and superb braking effect. It can be adjusted and maintained easily. Based on different bending angles of paperboards, variable-frequency air volume adjustment ensures smooth paper-feeding process.

8) Scraps of paper can be removed from the paperboard with a brush, a fan and a dust remover.

9) The top roll of paper feeding system with outside diameter of 145mm is a high-thickness seamless steel tube coated with wear-resistant rubber. It not only keeps flexible and ensures wear-resistant surface, but also reduces the number of squashed paperboards.

10) The lower roll of paper feeding system with outside diameter of 145mm is a seamless steel tube. It is embossed-surface ground and chrome plated.

11) Two rolls are driven using an Oldham coupling in order to reduce wear and provide stable transmission.

12) The clutch is electrically controlled and attached with an audible alarm which will continuously sound during operation to ensure the security of operators.

13) The drive shaft is equipped with an electromagnetic friction clutch to protect the motor from being burnt in the event of overload or malfunction.

14) The paper feeding unit, printing unit and slotting unit are designed with auto-zero function.

15) The printer slotter is equipped with a pneumatic interlock device.

B: Printing Unit

1: Printing Roll

1) The printing roll outside diameter is 275.6mm. The plate outside diameter reaches 290mm. Different models are designed with different sizes.

2) The printing roll is manufactured using a superior-quality, high-thickness seamless steel tube. It is surface ground and chrome plated.

3) Balance correction for stable operation of the printer slotter

4) Single-side locking allows the printing plate to be positioned accurately, conveniently and quickly.

5) The printer slotter is suitable for 10mm plate strips.

6) When the printing plate is assembled or disassembled, both clockwise and anticlockwise running are electrically controlled by the foot operated switch.

2: Impression Roll

1) The impression roll outside diameter is 174mm. Different models have different outside diameters.

2) The high-thickness seamless steel tube is surface ground and chrome plated.

3) Balance correction for stable operation of the printer slotter

4) The caliber of the press roll is adjusted by a self-locking system for a range from zero to 11mm.

3: Anilox Roll

The anilox roll has three colours. These three steel anilox rolls are respectively designed with 200 wires, 220 wires and 240 wires.

1) This printer slotter adopts the anilox roll with 164.3mm diameter.

2) The high-thickness seamless steel tube is surface ground and chrome plated.

3) Consistent grid points and uniform inking extends the service life of both printing plate and rubber roll.

4) Forming a speed difference between the rubber roll and anilox roll when rotating provides the rubber roll with deinking function.

5) The paper feeding system is configured with a pneumatic automatic lifting device. At the process of printing, the anilox roll declines to touch the printing plate. When the printing process is over, the anilox roll rises to be separated from the printing plate.

The metal anilox roll is produced in Wuxi City, Jiangsu Province.

4: Rubber Roll of Ink Distribution System

1) The rubber roll outside diameter reaches 168.3mm. Please note that different models have different outside diameters.

2) The high-quality seamless steel tube is coated with durable, corrosion-resistant and wear-resistant rubber.

3) The rubber roll undergoes special grinding process, providing superb ink transfer effect.

4) The caliber of the rubber roll is adjusted by a self-locking system for a range from zero to 3mm.

5: Unit Adjustment Mechanism of the Printer Slotter

1) Planetary gear structure

2) Digital display type unit indication makes the operation convenient, intuitive and accurate.

3) Controlled by PLC with touch screen, the printing unit can be digitally adjusted at 360 degrees no matter when it runs or stops working. The precision of adjusting the unit reaches up to 0.35mm.

4) The printing roll is designed with a frequency converter to adjust the unit, providing fast auto-zero and plate adjusting as well as precise plate adjusting.

5) First, all units of the printer slotter and paper feeding system are automatically returned to zero with precision up to 0.5mm. Then, the unit will be adjusted roughly and automatically. After a trial of printing, accurate adjustment can be conducted to greatly reduce the waste paperboard.

6: Ink Recycling System of the Printer Slotter

1) A pneumatic diaphragm pump is used to supply ink stably. It is operated and maintained easily.

2) The pneumatic pump is not allowed to pump ink until the rubber roll and anilox roll are gathered up.

3) A filter screen is used to remove impurities from ink.

7: Fixed Device of the Printing Unit

1) When the unit is separated or adjusted, the pneumatic braking mechanism limits gear rotation and maintains the original gear fixed point.

8: Axial Adjustment Mechanism

1) The axial orientation adopts electrical adjustment mechanism with control range from -10mm to +10mm.

2) Digital display type position indication makes operation convenient, intuitive and accurate.

C: Slotting Unit of the Printer Slotter

1) Paperboard is not broken easily after creasing.

2) Its intermittent dial is manually adjusted.

3) The caliber of the creasing wheel is manually adjusted with the dial to show the adjustment data.

4) The slotting knife is 7.0mm wide. It is made of alloy steel and becomes gear shaped after heat treatment. Double trimming knives provide high sharpness and high precision.

5) The caliber of the slotting boss is manually adjusted with the dial to show the adjustment data.

6) The slotting unit adjustment mechanism is designed with planetary gear structure.

7) Controlled by PLC, the slotting unit can be electrically and digitally adjusted at 360 degrees.

8) The movement of the upper boss and lower boss are linked so the two knives stay aligned during movement.

D: Die Cutter of the Printer Slotter

1: Operating Function

1) Without die cutting, the die roll and rubber roll will be automatically separated via an air-cylinder eccentric device to extend the lifespan of rubber and cutting die.

2) Planetary gear structure

3) The slotting unit is controlled by PLC and electrically and digitally adjusted at 360 degrees.

4) Electrical and digital adjustment, transverse movement, adjustment distance of approx. 10mm

5) The printer slotter is equipped with a rubber correcting device, allowing the rubber roll to be corrected repeatedly for use. A belt is equipped for conveyance.

2: Die Roll (Lower Roll)

1) The outside diameter of the die roll (concluding the cutting die) reaches 239.2mm. Please note that different models come with different outside diameters.

2) The die roll is made of cast steel. It is surface ground and chrome plated.

3) Balance correction for increased stability of operation

4) The pitch of the screw hole fixed by a cutting die is 100mm in axial direction.

5) The suitable cutting die is 25.4mm high.

The thickness of the wood die varies from 16mm to 18mm for three-layer board and from 13mm to 15mm for five-layer board.

3: Rubber Roll (Upper Roll)

1) Outside Diameter is 272mm.

2) An alloy steel seamless tube is surface ground and chrome plated.

3) Balance correction for increased stability of operation

4) The caliber of the cutting die is manually adjusted.

5) Rubber is 10mm thick and 200mm wide. It can be used up to 6 million times normally.

6) Up to 35mm of mechanical transverse movement

E: Stacker of the Printer Slotter

1) Connection arms can be operated manually or automatically.

2) The speed of connection is the same as feeding. It can be adjusted different to the feeding speed.

3) Stacked height reaches 1700mm.

4) The up and down of transport bed is controlled by strong chain.

5) The paper-receiving platform is installed with an anti-fall device to secure the operator.

6) A pneumatic controlled plate will be pop-up to hold the coming paperboard, when the pile reaches a pre-set height.

7) Flat belts with fold can prevent paperboard from falling.

8) The tensions of the belts for connection arm can be adjusted independently, no equal length restriction.

| Model | KYS-920 | KYS-1224 | KYS-1228 | KYS-1426 | KYS-1526 |

| Diameter of Printing Roll (including plate thickness of 7.2mm) | 290mm | 405mm | 405mm | 475mm | 475mm |

| Length of Printing Roll | 2000mm | 2400mm | 2600mm | 2600mm | 2600mm |

| Design Speed | 180pcs/min | ≤180pcs/min | 140pcs/min | 140pcs/min | 140pcs/min |

| Working Speed | ≤160pcs/min | ≤150pcs/min | ≤120pcs/min | ≤120pcs/min | ≤120pcs/min |

| Max. Printing Size | 850×2000mm | 1100×2400mm | 1100x2600mm | 1400×2600mm | 1400 × 2600mm |

| Max. Paper-Feeding Size | 910×2200mm | 1200×2600mm | 1200×2800mm | 1500×2800mm | 1500 × 2800mm |

| Min. Paper-Feeding Size | 260×650mm | 450×650mm | 400×650mm | 450×650mm | 450×650mm |

| Allowable Paperboard Thickness | 2 - 11mm | 2 - 11mm | 2 - 11mm | 2 - 11mm | 2 - 11mm |

| Wallboard Thickness | 60mm | 60mm | 60mm | 60mm | 60mm |

| Register Error | ≤±1.0mm | ≤±0.75mm | ≤±0.75mm | ≤±0.75mm | ≤± 0.75mm |

| Slotting Error | ≤±1.5mm | ≤±1.5mm | ≤±1.5mm | ≤±1.5mm | ≤±1.5mm |

| Main Power | 22KW | 22KW | 22.0KW | 22.0KW/30KW | 30KW |

| |

| | |

| Model | KYS-1624 | KYS-1632 |

| Diameter of Printing Roll (including plate thickness of 7.2mm) |

532mm | 532mm |

| Length of Printing Roll | 2200mm | 3000mm |

| Design Speed | ≤140pcs/min | 120pcs/min |

| Working Speed | ≤120pcs/min | ≤100pcs/min |

| Max. Printing Size | 1500×2200mm | 1500×3000mm |

| Max. Paper-Feeding Size | 1600×2400mm | 160×3200mm (Length of Paperboard Slot 3200mm, Length of Board Die Cut of 3000mm) |

| Min. Paper-Feeding Size | 500×650mm | 480×650mm |

| Allowable Paperboard Thickness | 2 - 11mm | 2 - 11mm |

| Wallboard Thickness | 60mm | 70mm |

| Register Error | ≤±0.75mm | ≤±0.75mm |

| Slotting Error | ≤±1.5mm | ≤±1.0mm |

| Main Power | 37KW | 37KW |

| | |

MAY KWA PRINTING MACHINERY CO., LTD.

Address: 51 Deyu road, Qiaonan street, Shiqiao, Panyu, 511400 Guangzhou city, Guangdong province, China

Tel.: +86-020-84877071