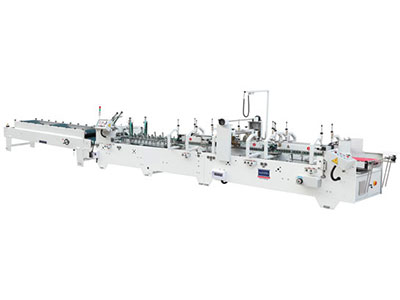

Flexo Printer Slotter, In Line Folder Gluer

Model: KYS-1224FG

Flexo printer slotter, in line folder gluer includes four parts like flexo printer, slotter, die cutter and in line folder gluer. According to actual needs, it has optional printing unit and die cutting unit. To optimize its performance, it employs imported electrical parts and bearings of famous brand from USA, Japan and European. Ceramic anilox rollers made in Taiwan are also applied. Besides, the machine is automatically controlled. Therefore, it is not only light and delicate in design, but comes with firm structure. With printing error ranging from -0.5mm to +0.5mm, our product enjoys sound reputation for being regarded as the high level and high standard machine.

The flexo printer slotter, in line folder gluer has the following features:

-

1. This machine adopts the design philosophy from CYM, Korea which uses three groups of wall plates to accomplish fixation of the folding arm, thus providing stable and shaking free folding arm.

-

2. The folding belt takes use of independent power. Each group of belt is driven by a motor which can prolong the service life of the belt by reducing its tensity.

-

3. This machine is equipped with vacuum paper sucking and conveying unit to ensure the stability of the paper transferring. This unit also has the function of deviation rectification.

-

4. The folding zone is equipped with three additional pressing lines as the compensation function for the insufficient pressing of the printing machine and solution for cutting error of the gluer machine.

5. The gluing head is glue spraying device imported from Anest Iwata, Japan. -

6. The computer can accomplish automatic order change and automatic order storage.

-

7. The counting and discharging zone adopts drop-paper feeding and dual alignment function, thus avoiding cutting error of the paper box.

-

8. The discharging zone adopts pushing discharging of the paper board, thus solving the problem that the traditional lifting discharging will cause collapsing of the paper board.

-

9. Both the printing zone and gluing zone can realize differential linkage. By entering the total width of the paperboard, the gluer belt can trace automatically, realizing minimum spacing which is 5-10cm between two pieces of paperboard. Then it can reduce the speed of the belt and improve the speed of the gluer to avoid unnecessary belt abrasion.

| Data | 1200 x 2400 | 1600 x 2800 |

| Max machine speed(pcs/min) | 200 | 180 |

| Max feeding size(mm) | 1200x2400 | 1600x2800 |

| Min feeding size(mm) | 500x700 | 500x700 |

| Skip feeding(mm) | 1500x2400 | 1900x2800 |

| Max printing area(mm) | 1200x2400 | 1600x2800 |

| Thickness of printing plate(mm) | 7.2 | 7.2 |

| Min slotting size | 115x115x115x115/180x60x180x60 | 115x115x115x115/180x60x180x60 |

| Max slotting depth(mm) | 300 | 400 |

| Max thickness of board(mm) | 12 | 12 |

| Item | KYS-920FG | KYS-1224FG | KYS-1526FG | KYS-1628FG |

| Maxi feeding size | 910*2000mm | 1200*2600mm | 1500*2800mm | 1550*2800mm |

| Effective print size | 900*1900mm | 1100*2400mm | 1400*2600mm | 1600*2500mm |

| Mini feeding size | 260*650mm | 450*650mm | 475*650mm | 480*650mm |

| Printing plate thickness | 7.2mm | 7.2mm | 7.2mm | 7.2mm |

| Economic speed | 200pcs/min | 150pcs/min | 100-120pcs/min | 80pcs/min |

| Main motor power | 15~30kw | 15~30kw | 15~30kw | 15-30kw |

| Print Register precision(4color) | ±0.5mm | ±0.5mm | ±:0.75mm | ±:0.75mm |

| Slotting precision | ± 1.5mm | ± 1.5mm | ±:1.5mm | ±:1.5mm |

| Slotting width | 7mm | 7mm | 7mm | 7mm |

1. Feeding unit

The feeding unit applies automatic systems. Side and back shielding board and feeding board adopt automatic position adjustment. However, both the front shielding board and the paper feeding roller can be manual adjusted. To ensure an unhindered paper feeding, blast absorption is employed in the assistant paper feeding system to adjust blast volume by pushing paperboard from back according to the way the cardboard bended. With automatic zero returning device, the parts of paper feeding, printing and fluting can be automatically or electrically returned to zero. In addition, try two pieces of paper before adjusted to the correct position, thus minimizing the waste. And the counter can show the number of paperboard pieces. Electric console is attached with an alarm ring which will continuously ring during operation to ensure the operators' security. Skip feeding unit is also installed. The suction device on the machine has greatly improved the quality of printing by cleaning up impurities on the plate surface. Moreover, the top roller of paper feeding system covered with hardwearing rubber also can be corrected by balance. The lower roller applies embossing and hard chrome plating. Light and hardwearing aluminum alloyed feeding board is applied, too.

2. Printing unit

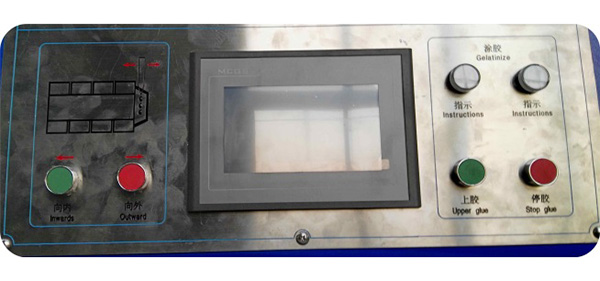

The grinded and chrome treated printing roller is a steel tube without gaps and can be corrected by balance and operated stably. And the printing plate can be changed quickly. Both clockwise and anticlockwise running are controlled by the foot operated switch. The intermittent dial on the press printing roller can be manual adjusted and the construction of orientated adjustment is planet like gearing wheel. The printing unit applies PLC and can be controlled by touch screen, so it can be electrically and digitally adjusted at 360 degree. Printing orientation fixed device and air operated breaking mechanism are also adopted. When the machine and the console are separated or the orientation is adjusting, the breaking mechanism will limit the rolling of both machine and console and keep the original fixed position of the gearing. There is an automatically recovering system after clean the printing plate. The horizontal orientated position can be adjusted digitally with the adjustment distance 20mm.

3. Ink system

The steel reticulated roller is grinded and hard chrome treated to obtain good ink transmission effect. Besides, hardwearing rubber is employed for coverage. However, the ceramic reticulated roller is ceramic grinded. The reticulation which is optional is carved by laser light. Furthermore, the easily cleaned ink trough can be loaded and unloaded.

4. Slotting unit

The pre-pressing wheel will be anti-breaking with the cardboard via pre-pressing line and its intermittent dial is manual adjusted. The top pressing line wheel will not break the paperboard for being covered with fine rubber. Both the pressing liner wheel and the bottom of the slotting cutter can be manual adjusted with the dial to show the adjustment data. The bottom of the slotting cutter will be electrically adjusted in horizontal orientation. The slotting cutter with the width 7mm is made from qualified steel alloy and becomes gear shaped after heat treatment and grinding. The shaped double blades accurately cut the sides of paperboard. In addition, the orientation of slotting cutter is adjusted by a planet like and gearing shaped mechanism. Integrated control with PLC and touch screen, the orientation of slotting cutter can be electrically and digital adjusted at 360 degree. With the10.4 inches touch screen on the control panel, paperboard feeding, printing, slotting and pattern cutting can be can easily controlled. What's more, the portable bottom model of aperture is equipped.

5. Auto Stacker

Connection arm can be manually or automatically operated. And tension of the transfer belt at the connection arm can be adjusted individually with no equal length restriction. The transport bed is controlled by strong chain and motor with brake, with the height up to 1600mm. The transport bed automatically adjusts its position according to the board stacking height. The pneumatic driven carrier plate will pop-up and hold the coming carton sheet when the pre-set height arrives. The flat wrinkle belts will avoid the sliding down of carton sheet. The side guide adjusted manually. The adjusting data is readable with one cylinder-adjusting device beside.

6. In Line Folder Gluer System

It includes a stacking and squaring unit. Digital controlled glue head and the belt speed can be micro adjusted. Also, length of feed and take-off belts is adjustable.

Easily cleaned gluer is employed to deliver smooth and uniform gluing. And the roller is synchronized with main unit and freewheels when machine is turned to prevent glue from drying and building up on the wheel. Electrically micro adjusted dual paper folding arms are digitally positioned. Nylon-core adjustable roller has a long life span. Feeder belt has springs and shock attenuates to avoid excessive pressure on paper.

MAY KWA is a professional flexo printer slotter, in line folder gluer manufacturer and supplier in China. We also offer carton making machine, die cutting creasing machine, flute laminating machine, window patching machine, and much more.

Related Products

Carton Printing Machine | Cardboard Packaging Box Machine | Paper Packaging Machinery Manufacturer

MAY KWA PRINTING MACHINERY CO., LTD.

Address: 51 Deyu road, Qiaonan street, Shiqiao, Panyu, 511400 Guangzhou city, Guangdong province, China

Tel.: +86-020-84877071