- Home

- Products

- Die Cutting Creasing Machine

- MY-1050T Automatic Die Cutting and Foil Stamping Machine

MY-1050T Automatic Die Cutting and Foil Stamping Machine

- The MY-1050T automatic die cutting and foil stamping machine is suitable for die cutting, creasing, foil stamping, cold and hot pressing of paper box, hang bag, Logo, invitation card and some other paper packaging in paper packaging industry. It is the key equipment for paper packaging manufacturers.

- High quality comes from fine machining. This machine adopts 9 servo motors from Mitsubishi, PLC programmable controller from Mitsubishi and Omron, human-computer interface, industrial control and monitoring system from internationally famous brands which can match perfectly with fine machining technology, thus featuring modern and intelligent performance. So the operation is easy and convenient.

- We developed an innovative foil conveying method which adopts bidirectional foil conveying. Two of them are transverse and three are longitudinal. You can adopt setting of five axis linkage, you can also choose the direction of the 7 axis according to the actual application. Any foil conveying mode can be adopted for different process requirements, thus realizing free foil rewinding and releasing and precise stamping.

- The brand new heating method has 16 temperature control area which can be adjusted according to your own requirements to save electricity. The heating parts can be changed according to the results of the self inspection of the heating system.

- The innovative multi-point complementary gripper positioning technology can eliminate the positioning error caused by abrasion of the positioning parts and chain injuries fundamentally. You can keep the machine precise only by a bit attention and easy adjustment.

- The electromagnetic jet blowing technology enables smooth foil stamping separation.

- The servo driven pressure adjusting system can carry out automatic control of abnormal running of the machine such as abnormal temperature, paper breaking, missing stamping etc., thus avoiding foil breaking and wasted products caused by miss stamping.

| Max.sheet feeding size | 1050*740mm |

| Min.sheet feeding size | 400*360mm |

| Max.die cutting size | 1040*730mm |

| Max foil stamping size | 970*700mm |

| Max.foil stamping speed | 6500s/h |

| Max.cutting speed | 7500s/h |

| Max.pressure | 300tons |

| Die cutting accuracy | ±0.1mm |

| Heating zone | 16 |

| Heating temperature | 0-199℃ |

| Max.feeding pile height | 1280mm |

| Max.delivery pile height | 1100mm |

| Thickness of cardboard | 0.1-2mm |

| Thickness of corrugated paper | ≤4 mm |

| Weight | 18000KG |

| Total Power | 38KW |

| Dimensions | 5820*3865*2200mm |

(1) Louver feeding mechanism, max speed 10000s/h;

(2) Independent preloading unit, maintain working pile freely when stacking on preload pallet;

(3) Adjustable side blowers;

(4) Electromechanical double-sheet inspection mechanism;

(5) PLC and electronic coder control whole machine timing;

(6) Side lay and front lay detect paper position;

(7) Program controls air pump starting, ensuring each paper reaches front lays precisely;

(8) When start the machine at any time, reducing make-ready time greatly;

(9) Double-sheet malfunction inspection, time-delay stop to ensure taking paper out of the machine from the conveying unit;

(10) All side guides and front guides equipped with detection sensors;

(11) Main and auxiliary feeding pallets switch automatically, realizing non-stop feeding;

(12) Strong power sucking feeder, 4 pick suckers and 4 feed suckers, suckers angle can be adjusted according to the curve of paper;

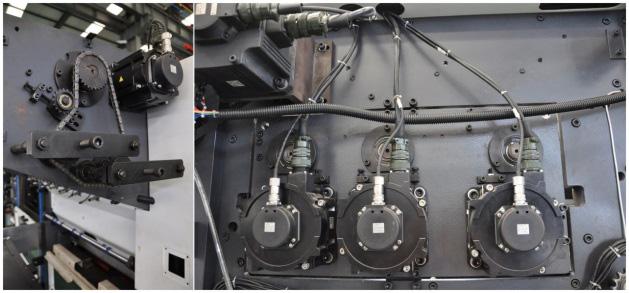

2. Foil Stamping and Die-cutting Unit

(1) Strong power industry computer controls 9 famous brand servo motors working for foil stamping and die-cutting;

(2) Mitsubishi PLC and high performance Fuji inverter ensure adjusting main motor speed smoothly;

(3) 2 Honeycomb panels, one for using the other one is back up;

(4) Machine base, wall plates, top and bottom tables are made of QT60 resin-bonded;

(5) Sand technical nodular graphite iron casting;

(6) Photoelectric sensor monitor frame position, pneumatic lock mechanism;

(7) Import torque limiter, protect machine when overloaded;

(8) Super-hard anode alumina alloy gripper bars and precise positioning st(9) ructures;

(10) Import high strength double-pitch gripper bar chain;

(11) Import high-strength nylon chain guider;

(12) Adjustable frame

3. Delivery Unit

(1) Automatic auxiliary delivery mechanism realize auto switch between main and auxiliary delivery pallets;

(2) Auto trimmer, hair brush pressure adjustable;

(3) Involution photoelectric sensor to prevent delivery pallet from going too high and paper rolling up;

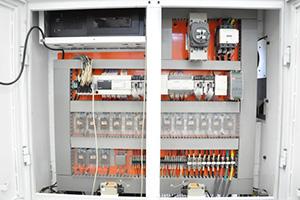

4. Electronic system

(1) Air conditioners keep the electrical control center working in constant temperature;

(2) All servo motors are imported from Mitsubishi;

(3) High performance industry computer ensures the electronic system and mechanical system working smoothly and efficiently;

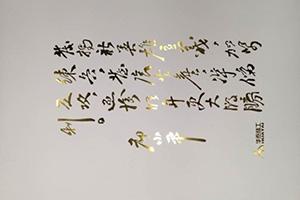

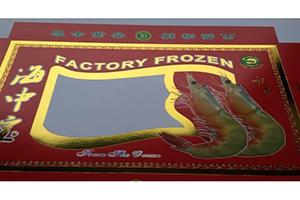

5. Foil stamping samples

MAY KWA PRINTING MACHINERY CO., LTD.

Address: 51 Deyu road, Qiaonan street, Shiqiao, Panyu, 511400 Guangzhou city, Guangdong province, China

Tel.: +86-020-84877071