- Home

- Products

- Die Cutting Creasing Machine

- MY-1050P Automatic Die Cutting and Creasing Machine

MY-1050P Automatic Die Cutting and Creasing Machine

- The MY-1050P automatic die cutting and creasing machine can be used for die cutting, creasing and cold pressing of paper box, hand bag, Logo, invitation card and some other paper packaging in packaging industry. This machine is also equipped with automatic waste stripping unit after die cutting. It is the key equipment for paper packaging manufacturers.

- The imported PLC programmable controller can realize fully automation of paper feeding, die cutting, stripping and paper discharging. The machine is also equipped with non-stop paper feeding and discharging function which is highly efficient and precise.

- The display system with human-computer interface can carry out real time monitoring of the machine operation, safety and product quality, thus providing all-dimensional intelligent control.

- The innovative multi-point complementary gripper positioning technology which is a detailed change can provide perfect and precise positioning.

- The light aluminum alloy stripping device features flexible running, wear resistance and high reliability. It is equipped with nearly 300 kinds of stripping unit supporting parts which can be chosen according to the practical use. The adjustment is easy and convenient.

- The positioning function of the stripping frame enables the whole replacement of the adjusting finished stripping template so that it can be used repeatedly. And the time of second imposition can be saved.

- At the end of the stripping process, the stripping unit frame will be lifted automatically.

| Maximum Sheet Size | 1050*740mm |

| Minimum Sheet Size | 400*360mm |

| Maximum Die Cutting Size | 1040*730mm |

| Die Cutting Precision | ±0.15mm |

| Max Feeding Pile Height | 1280mm |

| Max Delivery Pile Height | 1100mm |

| Max Die cutting Pressure | 300tons |

| Sheet Thickness of Cardboard | 0.1-2mm |

| Sheet Thickness of Corrugated Paper | ≤4mm |

| Maximum Speed | 7500s/h |

| Maximum Die cutting and Stripping Speed | 6500s/h |

| Dimensions | 5810*3865*2600mm |

| Total power of motors | 16.9KW |

| Gross weight | 17,000KG |

- High-speed feeder ensures high speed feeding of all kinds of papers;

- Reliable paper separating device,4-8 suckers improve adaptability and smooth feeding;

- Separating spring leaves and hair-brushes adjust conveniently, ensuring separating reliable, paper feeding smoothly;

- Coordinated with preloading unit and auxiliary delivery mechanism, realize non-stop feeding;

- Paper moving stably and smoothly, ensuring accurate positioning. Paper positioning can be adjusted while paper moving.

- High-quality side lay positioning mechanism equipped with sensors, it ensures accurate positioning before paper entering into grippers;

- Variable speeding conveying mechanism ensures high efficiency of paper feeding for thin paper and corrugated papers;

Die Cutting and Creasing Unit

High standard, heat treated steel drive worm and bronze wheel main drive. Toggle action die cutting movement;

- Precise driving gear and power-assisted device, ensuring stability of high-speed die cutting;

- Pneumatic chase-lock mechanism make die change quickly and die lock reliably;

- Adjustable chase design clips different dies conveniently;

- Adopt super-hard and durable steel plates;

- Optimized stripping frame driving mechanism on the main driving shaft, reducing striping power and making more stable and reliable;

- Stripping support frame can draw out device, thus shorten make-ready time greatly;

- Stripping structure is designed with top, middle, bottom 3 frames

- The top and bottom frame adopt center line structure, equipped with fine adjustment device to make the operation convenient and efficient.

- Negative stripping plate adopts quick lock-up mechanism, convenient and reliable.

- According to different die cutting needs, needle stripping and mould plates stripping are also optional;

- Realize convenient operation,high degree of automation and reduce the labor intensity greatly.

- Adopt side trimmer and back trimmer device, ensuring tidily delivery of paper pile;

- Adjustable expansion hair brush device, ensuring paper delivery smoothly;

- Equipped with automatic secondary delivery mechanisms, realized non-stop delivery, promoting the working efficiency.

- Non-stop sampling device realize real time checking die cutting precision

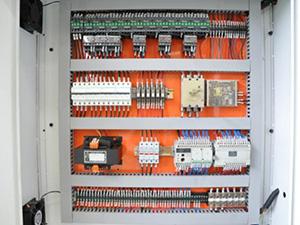

Electronic system

Electrical components and driving elements are all of internationally famous brands to ensure die cutting precision and reliability of running. Electric control system monitors in real time the running state of the whole machine by PLC, electronic cam and photoelectric switch, which is convenient for fault diagnosis.

Inquiry Form

MAY KWA PRINTING MACHINERY CO., LTD.

Address: 51 Deyu road, Qiaonan street, Shiqiao, Panyu, 511400 Guangzhou city, Guangdong province, China

Tel.: +86-020-84877071