- Home

- Products

- Flute Laminating Machine

- Automatic Cardboard to Cardboard Laminating Machine

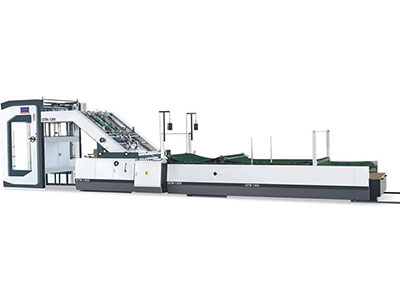

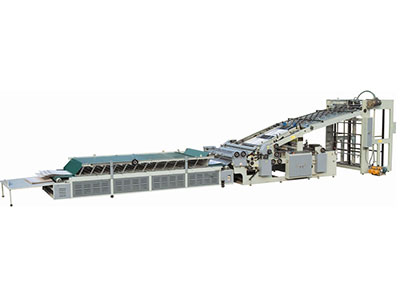

Automatic Cardboard to Cardboard Laminating Machine

Features:

The automatic cardboard to cardboard laminating machine produced by MAYKWA can be used for laminating of thin paper, cardboard, gray paperboard, art paper etc. It can satisfy the special process requirements such as double-sided printing and laminating, laminating of thin paper and thick paper etc. These processes requires high precision laminating with no deformation. This machine can be used for processing of wine box, shoe box, tags, toy box, gift box and some other fine packaging. The laminating finished paper features good flatness, high precision and good hardness etc.

The main parts of the machine are all imported from the famous factories at home and abroad which features long service life and high stability. The electrical components adopts supporting parts from internationally famous brands to ensure high reliability of the electrical components in using. This machine is equipped with innovative design of paper feeding structure which has five paper sucking device and four feeding device, differential position alignment, synchronous laminating etc. The products are certified by CE. The other parts are from internationally famous brands, thus ensuring stable machine performance. This machine realized fully automatic monitoring of paper feeding, position alignment, laminating and paper discharging. It also has the functions of automatic inspection, failure display and alarming with sound.

| Model | BKJ-1307 | BKJ-1310 | BKJ-1410 |

| Max sheet size(L*W) | 1270*720mm | 1270*1000mm | 1410*1410mm |

| Min sheet size | 500*380mm | 500*400mm | 500*400mm |

| Thickness of face paper | 100-800gsm | 100-800gsm | 100-800gsm |

| Thickness of bottom paper | 200-2000gsm | 200-2000gsm | 200-2000gsm |

| Working speed | 150sheets/min | 120sheets/min | 120sheets/min |

| Front lay laminating difference | ±0.5mm | ±0.5mm | ±0.5mm |

| Total weight | 9000kgs | 9000kgs | 11000kgs |

| Total length | 10500mm | 10500mm | 12000mm |

| Operation space | 3000*13500mm | 3000*13500mm | 3500*13500mm |

| Total power | 16.5kw | 16.5kw | 24.5kw |

| | | |

-

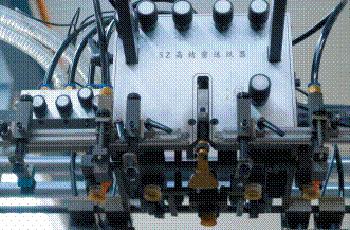

+Five sucking and four forwarding high precision feeder:

We use five sucking and four forwarding paper feeder to make paper output more stable and reliable. You can adjust the height or angle of each sucker according to the paper quality to make the machine running with high efficiency. -

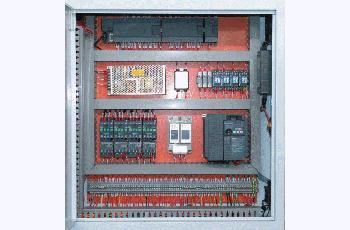

+Electrical Part:

The man-machine interface can reflect the status of running or malfunction timely. The world – brand electrical elements ensure the stable performance of the machine. -

+Driving Part:

We use synchronization sprocket drive, so that the machine can run more smoothly with higher accuracy. -

Chasing registration and side lay alignment structures:

Using the different speed between conveying and front lay to register the sheets precisely. The side lay are synchronized with the paper conveying. -

+Gluing Part:

The unique anilox-type roller makes glue even and saving. Compared with traditional anilox roller, it can save 5 gram glue per square meter.

MAY KWA PRINTING MACHINERY CO., LTD.

Address: 51 Deyu road, Qiaonan street, Shiqiao, Panyu, 511400 Guangzhou city, Guangdong province, China

Tel.: +86-020-84877071